Fire Protection Solutions for the Bioenergy Industry

Preventing fires and explosions to safeguard biomass production

As demand for wood pellets rises, so does the risk of fires along fast-moving production lines. Combustible dust generated during processing can easily ignite due to mechanical issues or friction. To support the sustainable growth of bioenergy, fire prevention must be a top priority—combining innovation with robust safety systems to keep operations running safely and efficiently.

Fire and Explosion Risk in Biomass Handling

Biomass materials like wood chips and pellets pose serious fire and explosion risks during transport and storage. Self-heating, combined with the accumulation of fine, flammable dust, creates a highly combustible environment. Dust layers in silos can ignite at just 260°C (500°F), while sparks or hot particles—detectable by Firefly systems—can trigger fires at temperatures as low as 250°C (480°F).

With 52 fire and explosion incidents recorded in U.S. pellet plants since 2001, and biomass gaining traction as a key energy source, proactive safety measures are vital. Reliable detection and suppression technologies are essential to support the industry’s safe and sustainable growth.

Fire Safety Solutions for the Bioenergy Industry

FNA Inc. delivers advanced, customized fire protection systems for the bioenergy sector. Using high-sensitivity IR detectors to spot sparks and hot particles early, our systems activate full-cone water spray to extinguish threats before ignition occurs—protecting every stage of pellet production.

As demand for renewable energy accelerates, reliable fire prevention is essential for safe, uninterrupted operations and sustainable growth in the wood pellet industry.

Custom Solutions for the Bioenergy industry

The bioenergy sector faces unique fire and explosion risks—from combustible dust to high-temperature mechanical processes. At FNA Inc., we design custom fire protection systems engineered specifically for biomass environments. Our solutions combine precise spark detection, rapid suppression, and seamless integration into pellet production and handling lines—ensuring safety without compromising efficiency

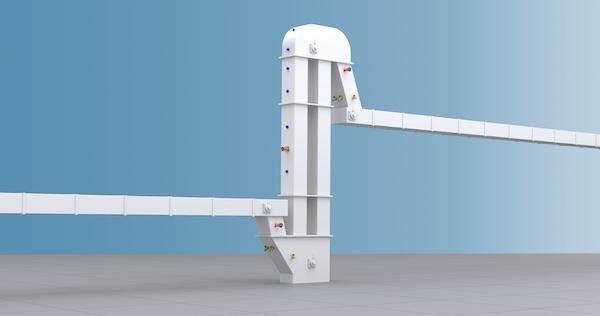

Firefly Mill Room Protection™

The Firefly Mill Room Protection is a unique solution on the market combining a Fire Prevention Solution; Firefly Spark Detection System with a Fire Protection Solution; Firefly Quick Suppression System. Firefly’s unique Spark Detection System is based on True IR spark detectors that are insensitive to daylight. Both Firefly Spark Detection and Extinguishing System are certified according to FM, Factory Mutual and VdS, Schadenverhütung GmbH.

As the first company in the world, Firefly launched a third party certified Quick Suppression System. The Firefly Quick Suppression System is a complete system designed for extremely quick detection and efficient water mist suppression of flames or fires in and around critical machinery and high-risk areas. The system has been fire tested against the test protocol DFL TM170307-1261 and verified by the DNV.

Firefly has solutions for protecting the whole Wood Pellet Manufacturing Process including Filters and Silos.

Key Benefits

- Quick System Response Time

- Minimum Water Usage

- Third Party Approved System

- Precision Detection

Certifications

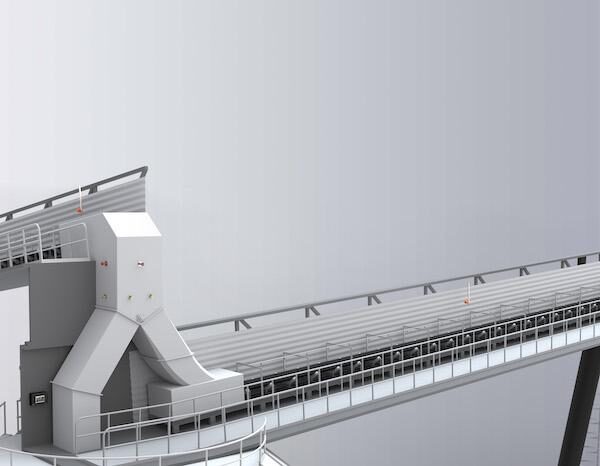

Firefly ConveyorGuard™

A fire in a belt conveyor is often hard to extinguish and can spread very quickly. In the worst case it can spread to surrounding material stacks and could last for weeks, causing major loss of revenue and production downtime.

The purpose of the Firefly ConveyorGuard™ solution is to automatically detect and suppress a fire at an early stage and to stop the conveyor belt as quickly as possible. The Firefly ConveyorGuard™ solution can be complemented with Firefly open area flame detectors and/or LTS cable.

Key Benefits

- Quick System Response Time

- Minimum Water Usage

- Third Party Approved System

- Precision Detection

Certifications

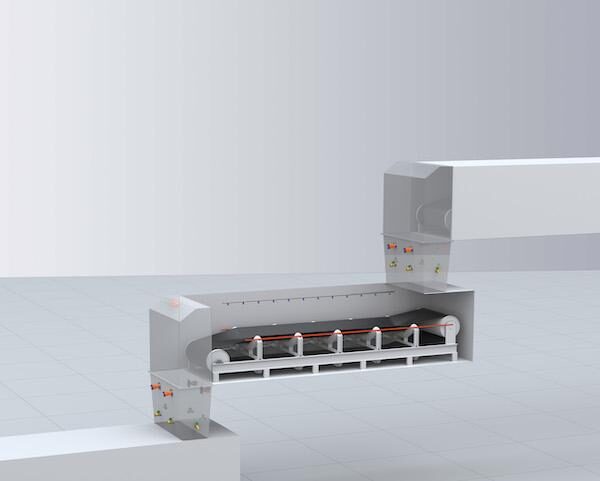

Firefly ShredderGuard™

Frequent fires in shredders often result in production downtime and loss of revenue. A fire in a shredder can spread very quickly. Therefore, Firefly has developed Firefly ShredderGuard™, a Quick Suppression System that can withstand the tough conditions in and around a shredder. The main focus of the Firefly ShredderGuard™ solution is to detect and extinguish a fire in a shredder as quickly as possible. This is why a Firefly safety system always consists of three main integrated functionalities: detection, extinguishing and control.

By integrating different techniques (flame detection, True IR-detection, full-cone water spray extinguishing and water mist suppression) into one solution, Firefly provides optimal safety for the protection of shredders.

Key Benefits

- Quick System Response Time

- Minimum Water Usage

- Third Party Approved System

- Precision Detection

Certifications

Director of Operations at Factory X

John Bennick

FNA took the time to understand our challenges and came up with customized solutions that we never considered.

Unique Fire Protection Solutions for the bioenergy industry

Ultra Quick System Response Time

The Quick Suppression System, which is part of our Mill Room Protection™ solution, operates with high performance flame detectors for extremely quick detection. The efficient water mist system has remarkable suppression capabilities which reduce damages on machinery.

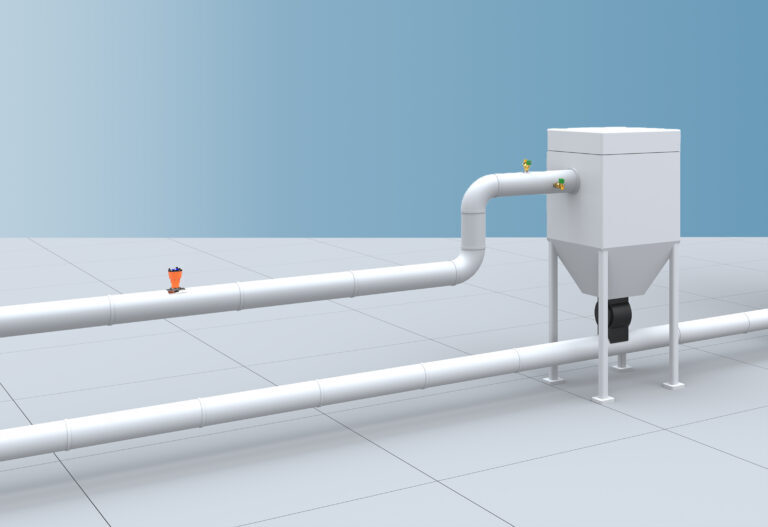

FIREFLY FILTER PROTECTION

Dust extraction systems are vital to take care of dust generated in dry bulk handling processes. The risk in these units is considered very high due to the high concentration of dust. Firefly’s FM-approved Spark Detection and Extinguishing System will efficiently prevent ignition sources from entering the risk zones.

Precision Detection

The True IR Spark detectors enable Precision Detection of ALL types of ignition sources such as hot black particles, glowing embers, and sparks. The detectors are insensitive to daylight. Systems are also equipped with Multi-Channel flame detectors using advanced algorithms for Precision Detection of flames with high immunity to false positives.

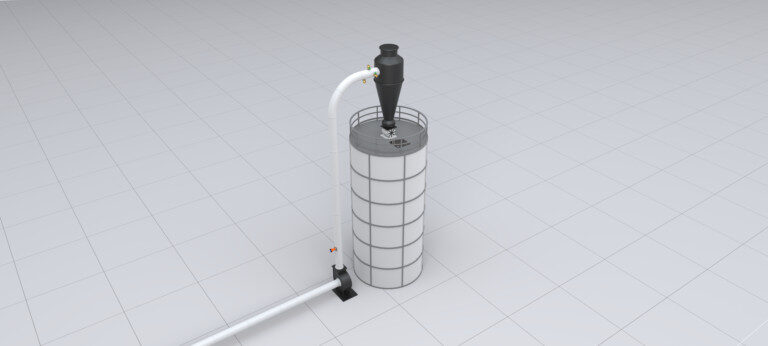

FIREFLY SILO PROTECTION

Firefly’s True-IR detectors will prevent ignition sources (such as hot black particles, embers and sparks) from entering the silo. Full-cone water spray is one of the methods used to extinguish the ignition source in milliseconds after detection. The detection of a smouldering fire inside a silo is known to be very difficult. Firefly’s MGD, a gas analyzer, commonly known as “electronic nose,” is designed to detect the earliest stages of a combustion process, for example the self-heating process of an organic material.

Downloads

Firefly Pellet Industry

Firefly Spark Detection System

Firefly EXsolvo®

Firefly EXIMIO™

FM Approved Fire Protection

All our fire prevention products are FM approved, meeting the highest safety standards. As the official North American distributor for Firefly, we provide cutting-edge protection, including the only FM-approved spark detection system for high-temperature particles.

Industries We Protect

Fire Safety Solutions for High-Risk Industries. We protect industries where fire risks are high, ensuring operational safety and business continuity.