Fire Protection for Port Facilities and Logistical Terminals

Safeguarding Port Operations Against Fire Hazards

Port facilities and logistical terminals are critical hubs in the global supply chain, operating around the clock to manage vast quantities of bulk materials. The continuous movement and handling of these materials introduce significant fire risks, which can lead to operational disruptions, equipment damage, and safety hazards for personnel.

Identifying High-Risk Areas

Several factors contribute to the heightened fire risk in port environments:

- Material Handling Processes: The transfer of bulk materials such as wood chips, grains, and biomass can generate fine dust particles. These particles are highly combustible and can accumulate in equipment like conveyors, chutes, and silos.

- Mechanical Failures: Equipment malfunctions, such as stalled rollers or bearing failures, can produce heat through friction, igniting nearby combustible materials.

- Hydraulic Systems: Approximately 90% of yard equipment fires are attributed to hydraulic oil leaks. Pressurized hydraulic oil can spray up to 10 meters, and with an ignition temperature of around 500°C, it poses a significant fire hazard when in contact with hot surfaces.

- Electrical Equipment: The increasing use of electric vehicles and machinery introduces risks associated with lithium-ion batteries, which can experience thermal runaway and ignite if damaged.

Custom Solutions for Port Facilities and Logistical Terminals

We provide custom-engineered fire protection systems designed specifically for the high-risk environments of port facilities and logistical terminals. Our solutions are built to detect and suppress ignition sources early—ensuring continuous operations, asset protection, and personnel safety.

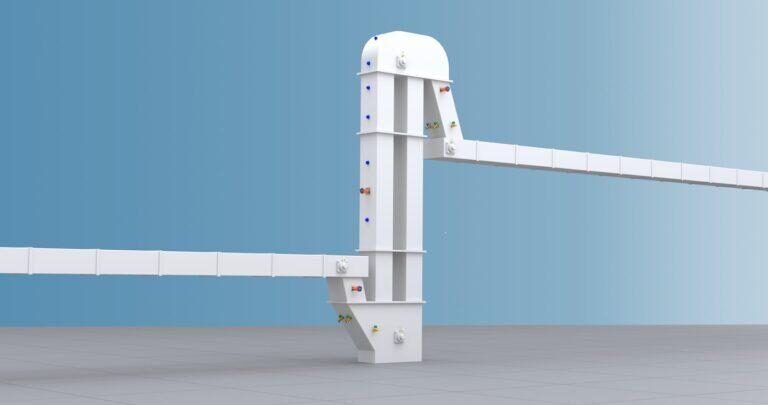

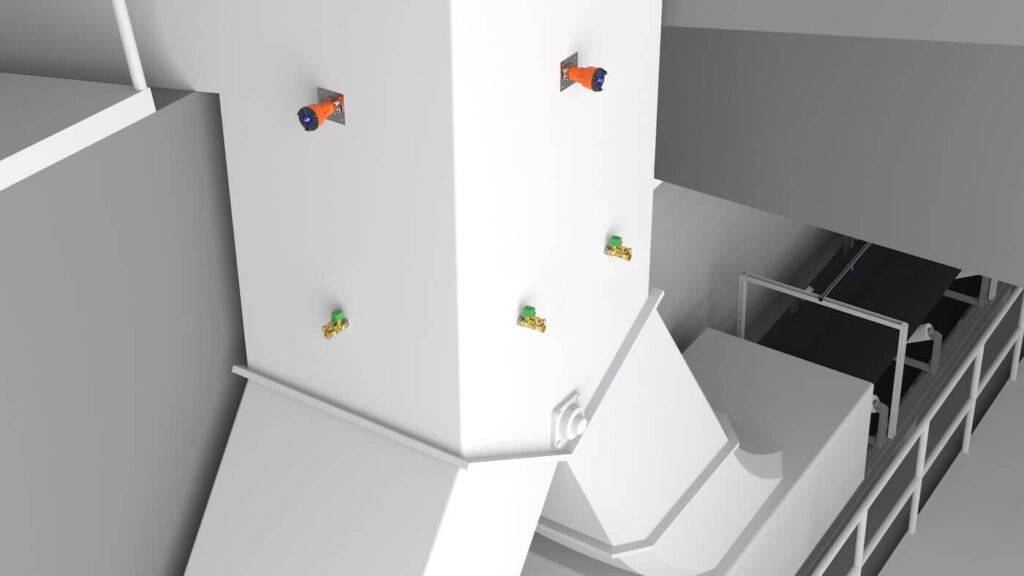

Firefly ElevatorGuard™

The dusty atmosphere inside an elevator is ideal for a fire or a dust explosion. The properties of a bucket elevator also makes it more complicated to protect. A fire can start due to ignition sources being fed into the elevator, but ignition sources can also be generated inside the elevator itself.

The Firefly ElevatorGuard™-solution includes FM-approved, True- IR hot particle detectors and full cone water extinguishing nozzles at the inlet and outlet of the elevator. At the inlet, the Firefly system will minimize the risk of any dangerous ignition sources to enter the elevator. If the root cause is inside the elevator, the system at the outlet will give an early indication of a beginning problem inside the elevator and minimize the risk of ignition sources leaving the elevator to downstream process parts.

Key Benefits

- Quick System Response Time

- Minimum Water Usage

- Third Party Approved System

- Precision Detection

Certifications

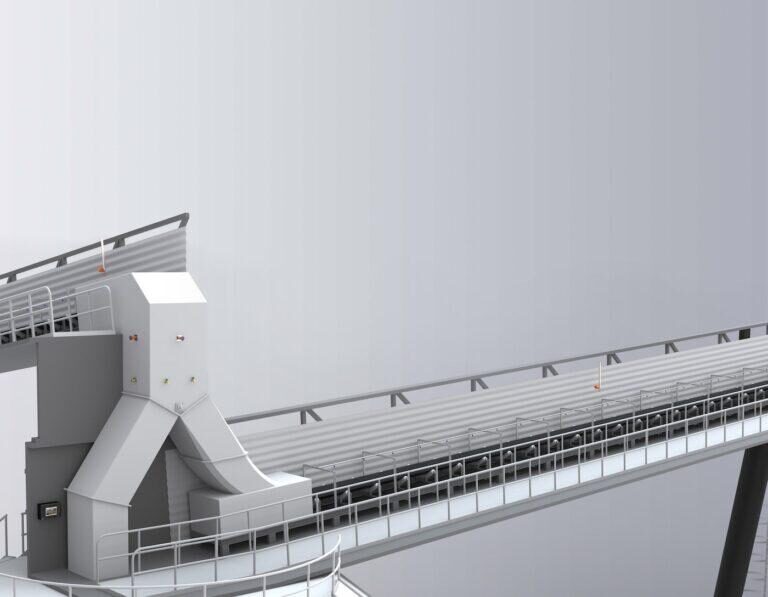

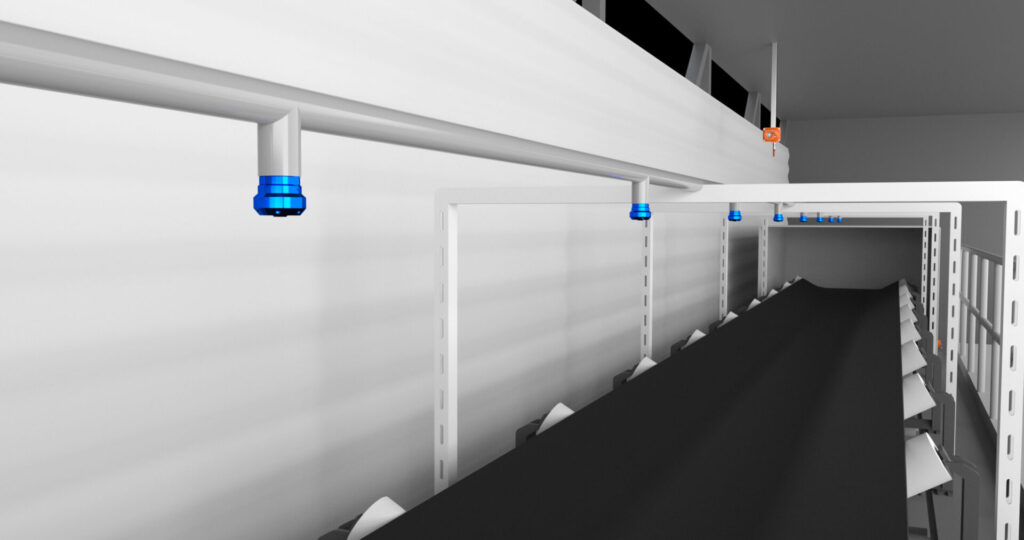

Firefly ConveyorGuard™

A fire in a belt conveyor is often hard to extinguish and can spread very quickly. In the worst case it can spread to surrounding material stacks and could last for weeks, causing major loss of revenue and production downtime.

The purpose of the Firefly ConveyorGuard™ solution is to automatically detect and suppress a fire at an early stage and to stop the conveyor belt as quickly as possible. The Firefly ConveyorGuard™ solution can be complemented with Firefly open area flame detectors and/or LTS cable.

Key Benefits

- Quick System Response Time

- Minimum Water Usage

- Third Party Approved System

- Precision Detection

Certifications

Director of Operations at Factory X

John Bennick

FNA took the time to understand our challenges and came up with customized solutions that we never considered.

Why Choose Firefly?

Ultra Quick System Response Time

The Quick Suppression System, which is part of our protection solution for shredders, operates with high performance flame detectors for extremely quick detection. The efficient water mist system has remarkable suppression capabilities which reduce damages on machinery.

Full – Cone Water Spray Extinguishing

Powerful extinguishing with a unique nozzle design and placement aimed to penetrate and cover the entire material flow. Activated within milliseconds after detection.

Precision Detection

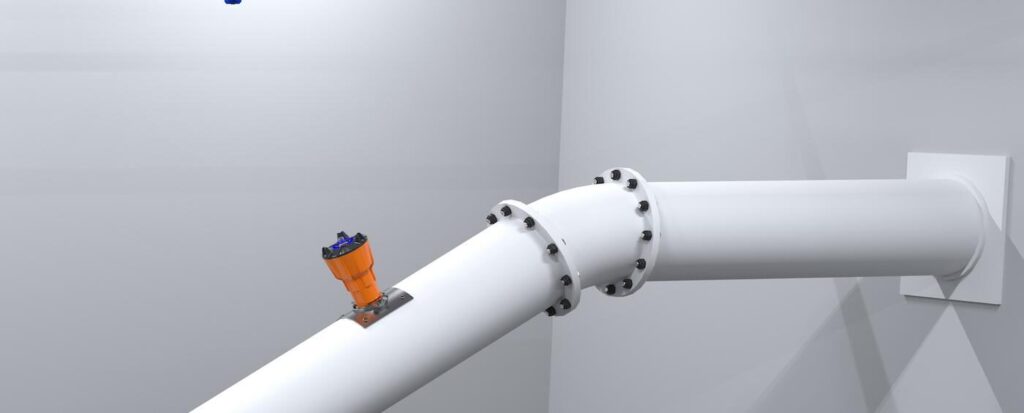

The True IR Spark detectors enable Precision Detection of ALL types of ignition sources such as hot black particles, glowing embers, and sparks. The detectors are insensitive to daylight. Systems are also equipped with Multi-Channel flame detectors using advanced algorithms for Precision Detection of flames with high immunity to false positives.

Excellent Suppression Capabilities

The Water Mist System with fire-tested and verified extinguishing capabilities utilizes very small amounts of water resulting in less impact on machinery, minimized production loss and down time.

Downloads

Firefly port and logistical terminals

Firefly ConveyorGuard™

Firefly EXsolvo®

FM Approved Fire Protection

All our fire prevention products are FM approved, meeting the highest safety standards. As the official North American distributor for Firefly, we provide cutting-edge protection, including the only FM-approved spark detection system for high-temperature particles.

Industries We Protect

Fire Safety Solutions for High-Risk Industries. We protect industries where fire risks are high, ensuring operational safety and business continuity.