Fire Protection Solutions for the Recycling Industry

Addressing Fire Risks in Recycling Operations

Recycling facilities handle a diverse range of materials, many of which are combustible. Processes like shredding and crushing increase the surface area of these materials, making them more susceptible to ignition. Additionally, the presence of contaminants such as oils, greases, and discarded lithium-ion batteries further elevates the risk of fires and explosions.

Common Fire Hazards in Recycling Facilities

Mechanical Failures

Equipment malfunctions, such as bearing failures or friction from moving parts, can generate heat and sparks.

Foreign Objects

Metal fragments or other non-combustible materials can cause sparks when processed.

Dust Accumulation

Fine particulate matter from materials like paper, plastic, or wood can become airborne and ignite.

Lithium-Ion Batteries

Improperly disposed batteries can undergo thermal runaway, leading to intense fires that are difficult to extinguish

Custom Solutions for the Recycling Industry

Recycling plants face high fire risks due to the presence of combustible waste and potential ignition from mechanical equipment. Firefly’s systems provide early detection and suppression to ensure safe operations.

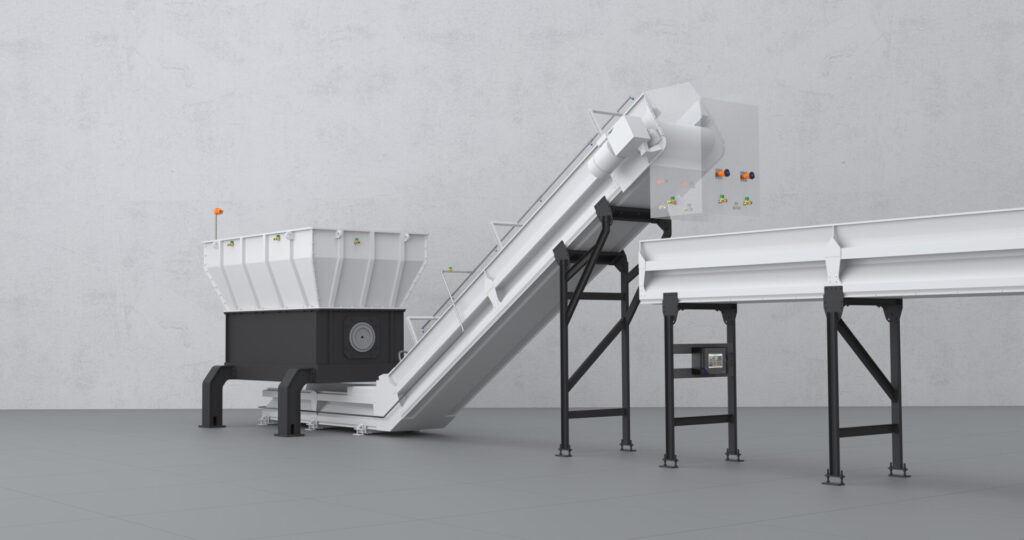

Firefly ShredderGuard™

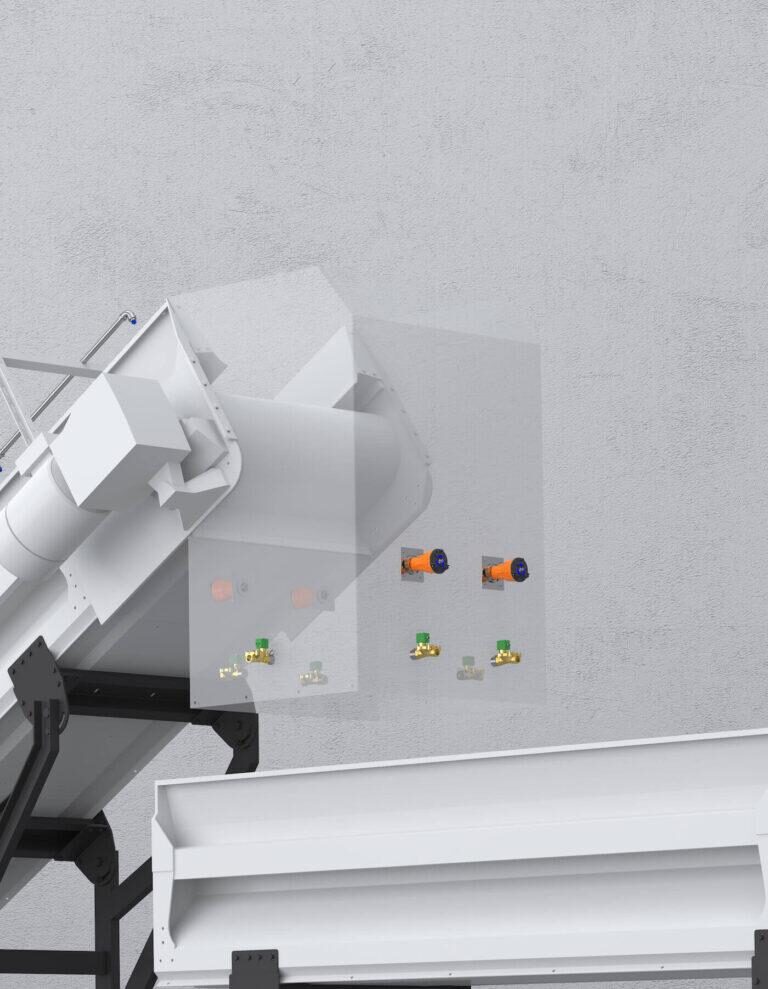

Frequent fires in shredders often result in production downtime and loss of revenue. A fire in a shredder can spread very quickly. Therefore, Firefly has developed Firefly ShredderGuard™, a Quick Suppression System that can withstand the tough conditions in and around a shredder. The main focus of the Firefly ShredderGuard™ solution is to detect and extinguish a fire in a shredder as quickly as possible. This is why a Firefly safety system always consists of three main integrated functionalities: detection, extinguishing and control. By integrating different techniques (flame detection, True IR-detection, full-cone water spray extinguishing and water mist suppression) into one solution, Firefly provides optimal safety for the protection of shredders.

Key Benefits

- Quick System Response Time

- Minimum Water Usage

- Third Party Approved System

- Precision Detection

Certifications

Director of Operations at Factory X

John Bennick

FNA took the time to understand our challenges and came up with customized solutions that we never considered.

Why Choose Firefly?

Ultra Quick System Response Time

The Quick Suppression System, which is part of our protection solution for shredders, operates with high performance flame detectors for extremely quick detection. The efficient water mist system has remarkable suppression capabilities which reduce damages on machinery.

Full – Cone Water Spray Extinguishing

Powerful extinguishing with a unique nozzle design and placement aimed to penetrate and cover the entire material flow. Activated within milliseconds after detection.

Precision Detection

The True IR Spark detectors enable Precision Detection of ALL types of ignition sources such as hot black particles, glowing embers, and sparks. The detectors are insensitive to daylight. Systems are also equipped with Multi-Channel flame detectors using advanced algorithms for Precision Detection of flames with high immunity to false positives.

Excellent Suppression Capabilities

The Water Mist System with fire-tested and verified extinguishing capabilities utilizes very small amounts of water resulting in less impact on machinery, minimized production loss and down time.

Downloads

Firefly ShredderGuard™

Firefly ConveyorGuard™

Firefly MGD

Firefly EXIMIO™

Firefly Spark Detection System

Firefly Quick Suppression System

FM Approved Fire Protection

All our fire prevention products are FM approved, meeting the highest safety standards. As the official North American distributor for Firefly, we provide cutting-edge protection, including the only FM-approved spark detection system for high-temperature particles.

Industries We Protect

Fire Safety Solutions for High-Risk Industries. We protect industries where fire risks are high, ensuring operational safety and business continuity.