Comprehensive Fire Safety for Woodworking Plants

Preventing Fires and Sawdust Explosions in Wood Processing

Wood is a highly valuable and widely used natural material. To maximize yield and efficiency, woodworking facilities often operate highly automated production lines with advanced, high-speed machinery. In such environments, even a brief production stop can result in costly downtime and substantial financial losses.

Unfortunately, fire and explosion hazards are a major concern across the wood industry—especially where sawdust, wood shavings, and hot surfaces are involved.

Fires: The Leading Cause of Loss in Wood Manufacturing

According to a 10-year study by leading insurance consultancy Risk Logic, fires and dust explosions account for nearly 75% of all financial losses in property insurance claims within the wood processing and furniture manufacturing sectors. In these environments, wood dust and oxygen are constantly present. A mechanical failure—such as an overheated bearing or a fan malfunction—can easily ignite dust, triggering a fire or, in worst-case scenarios, a powerful dust explosion.

Wood Dust: Highly Flammable, Easily Ignited

Fine wood dust and shavings accumulate quickly around woodworking equipment. These particles present a constant fire risk, especially in high-friction areas like cutting, sanding, or extraction systems.

- Layer ignition temperature: ~260°C

- Dust cloud ignition temperature: ~470°C

- Visual risk: Hot particles below 650°C may not glow—appearing as dark, “invisible” threats

Despite the lack of visible warning, these black particles can carry enough heat to trigger ignition.

Proactive Detection and Protection Systems for Woodworking plants

Woodworking plants handle flammable materials and produce large amounts of dust, making them prone to fire hazards. Firefly’s fire protection systems ensure early detection and rapid suppression.

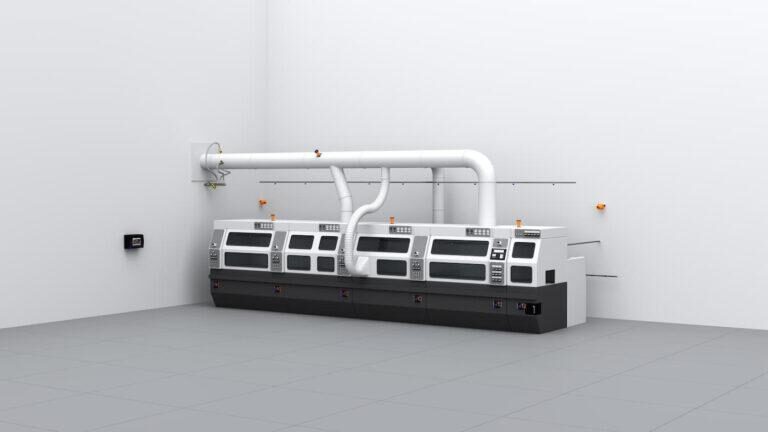

Firefly PlanerGuard™

In many cases, large amounts of shavings are accumulated in and around the open planer. When ignited, these shavings can cause rapid fires resulting in considerable damage. Firefly’s PlanerGuard™ solution for open planers monitors the machine by using flame detectors installed local to the area. Non-invasive water mist suppression aims at quick and effective suppression of the fire, even in the closed areas of an open planer.

Key Benefits

- Quick System Response Time

- Minimum Water Usage

- Third Party Approved System

- Precision Detection

Certifications

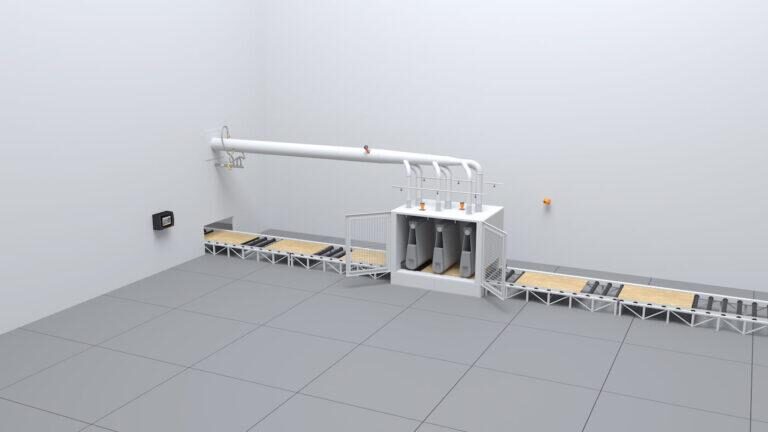

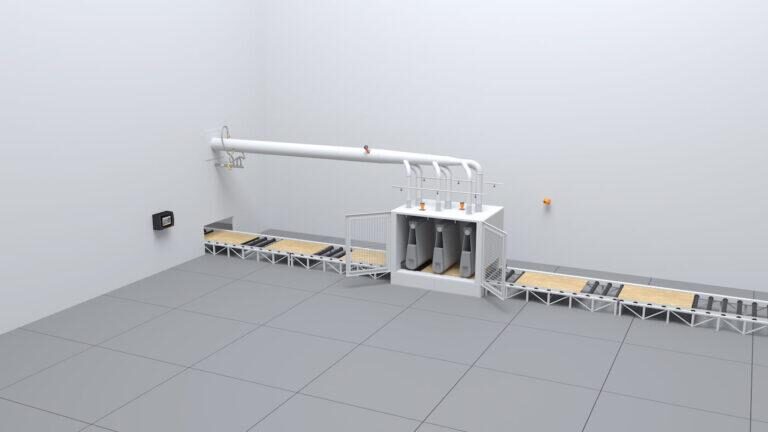

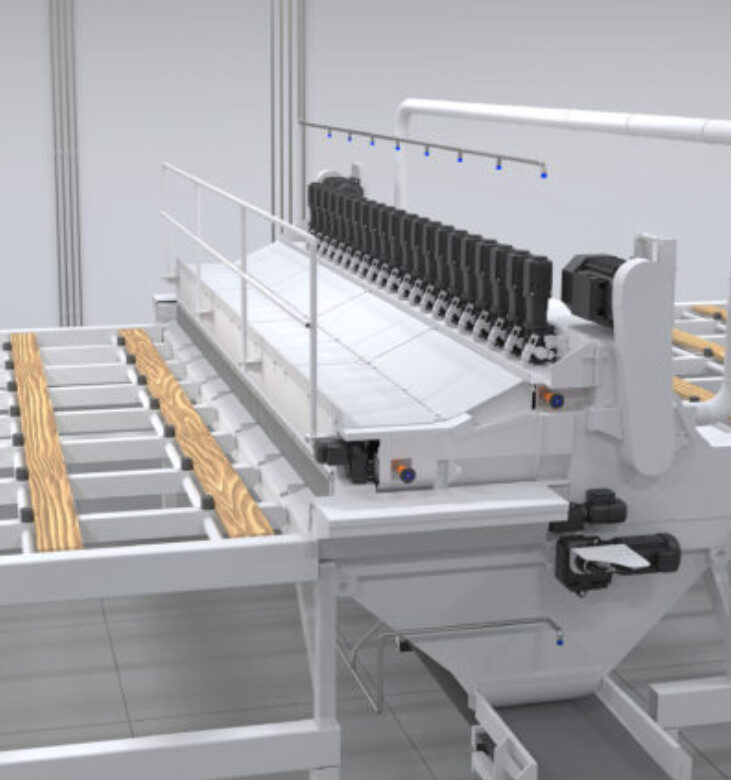

Firefly SanderGuard™

The fine dust generated by a sanding machine can, when ignited, give rise to severe dust explosions and rapid spread of fire. Firefly’s SanderGuard™ system solution is designed for all types of sanders.

Firefly’s SanderGuard™ system solution includes quick flame detection inside the sanding machine and water mist suppression, providing optimal protection of this important link in the production chain.

Key Benefits

- Quick System Response Time

- Minimum Water Usage

- Third Party Approved System

- Precision Detection

Certifications

Firefly Filter and Silo Protection

The bag house filter and silos are critical components in woodworking facilities but also pose significant fire and explosion risks. Fine dust particulates within the filter, coupled with high airflows, create ideal conditions for rapid fires or dust explosions if ignited by an external source. Silos, in particular, present additional challenges, as extinguishing a silo fire is complex and hazardous, often taking days or weeks to resolve, with a constant risk of explosion.

To mitigate these risks, Firefly offers innovative protection solutions. For filter protection, Firefly utilizes its unique True-IR detector HD400, capable of detecting sparks and hot particles with temperatures as low as 400°C (752°F). Positioned before and after the filter, these detectors are complemented by a powerful full cone extinguishing zone to swiftly address any detected threats. Similarly, for silo protection, Firefly employs the True-IR detector HD250, which can detect sparks and hot particles down to 250°C (482°F). Placed strategically before the silo or within drop chutes if materials are mechanically fed, these detectors are followed by an effective extinguishing zone to promptly suppress potential ignition sources.

By proactively addressing ignition risks before they reach critical equipment, Firefly’s solutions offer enhanced safety and peace of mind for woodworking facilities, ensuring the protection of valuable assets and personnel.

Key Benefits

- Quick System Response Time

- Minimum Water Usage

- Hot particle detection

- Insensitive to daylight

Certifications

Why Choose Firefly?

Ultra Quick System Response Time

The Quick Suppression System, which is part of our protection solution for shredders, operates with high performance flame detectors for extremely quick detection. The efficient water mist system has remarkable suppression capabilities which reduce damages on machinery.

FIREFLY FILTER PROTECTION

Dust extraction systems are vital to take care of dust generated in dry bulk handling processes. The risk in these units is considered very high due to the high concentration of dust. Firefly’s FM-approved Spark Detection and Extinguishing System will efficiently prevent ignition sources from entering the risk zones.

Precision Detection

The True IR Spark detectors enable Precision Detection of ALL types of ignition sources such as hot black particles, glowing embers, and sparks. The detectors are insensitive to daylight. Systems are also equipped with Multi-Channel flame detectors using advanced algorithms for Precision Detection of flames with high immunity to false positives.

Excellent Suppression Capabilities

The Water Mist System with fire-tested and verified extinguishing capabilities utilizes very small amounts of water resulting in less impact on machinery, minimized production loss and down time.

Director of Operations at Factory X

John Bennick

FNA took the time to understand our challenges and came up with customized solutions that we never considered.

Downloads

Firefly EXIMIO™

Firefly Spark Detection System

Firefly Quick Suppression System

Firefly Woodworking

Firefly EXsolvo®

FM Approved Fire Protection

All our fire prevention products are FM approved, meeting the highest safety standards. As the official North American distributor for Firefly, we provide cutting-edge protection, including the only FM-approved spark detection system for high-temperature particles.

Industries We Protect

Fire Safety Solutions for High-Risk Industries. We protect industries where fire risks are high, ensuring operational safety and business continuity.